Shangdong shangda rare earth materials co ltd is a leading Chinese privately owned corporation that specializes in manufacturing sintered Rare Earth Neodymium (NdFeB) permanent magnet and magnetic assembly. Since the company was founded in 2012, It has invested 23 million USD and has the annual production capacity of sintered NdFeB is over 3000 tons and assembling magnet components over 80,000 pieces each month.

Shangdong shangda rare earth materials co ltd is a leading Chinese privately owned corporation that specializes in manufacturing sintered Rare Earth Neodymium (NdFeB) permanent magnet and magnetic assembly. Since the company was founded in 2011, It has invested 23 million USD and has the annual production capacity of sintered NdFeB is over 3000 tons and assembling magnet components over 80,000 pieces each month.

Sintered NdFeB magnets are widely used in many areas, and the market demand for high temperature resistance magnet increasing sharply due to the rapid development of new energy vehicles and wind turbine industries.

Take a permanent magnet motor as an example, the ambient temperature of the motor magnet will be higher than 150 deg C under the high speed operation, then the magnet with lower intrinsic coercivity will be demagnetized. The most direct method to satisfy the high temperature application is enhancing the intrinsic coercivity of magnet. The conventional way to increase the intrinsic coercivity is adding the heavy rare earth elements in the alloy preparation process, such as Dy and Tb.

The thermal stability of the magnet will have a substantial improvement after added the heavy rare earth elements Dy and Tb to the NdFeB-alloys. The usage amount of Dy element in the HEV magnet even more than 10wt%. Due to the antiferromagnetic coupling effect between Dy and Fe, the Br and (BH)max value will decrease with increasing heavy rare earth element usage. On the other hand, the prices of heavy rare earth element are very expensive. How to make the high coercivity magnet with low Dy/Tb content is still a hotspot in the magnet industry, and the researchers called it HRE-Free magnets or Dy-Free magnets.

How to enhance the intrinsic coercivity of sintered NdFeB magnet in other ways?

Optimizing the grain size, grain boundary composition and its structure.

Grain refinement technology.

Grain boundary diffusion (GBD) technology.

Grain boundary doping technology.

The grain boundary diffusion (GBD) technology

What is grain boundary diffusion (GBD) technology?

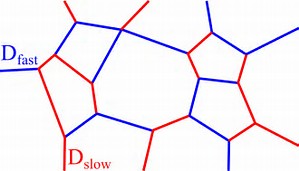

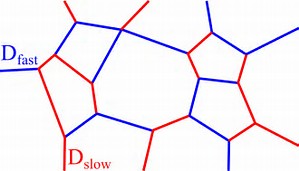

The heat treatment temperature will be higher than melting point of Nd-rich phase in the grain boundary diffusion (GBD) technology, then the Dy/Tb compound on the magnet’s surface can penetrate into the magnet through its grain boundary.

With the large increase of intrinsic coercivity at the same time, also ensure the Br value basically unchanged is the biggest advantage of grain boundary diffusion (GBD) technology.